Leaving Cert Engineering is a mixture of theory and practical work. It involves quite a bit of metalwork and metal-related theory but also includes other areas such as plastics, mechanisms, robotics and electronics. The practical side is composed of a practical exam (which usually takes place in May) and a project (which runs from October to March). The theory exam takes place in June and it contains quite a bit of choice in the exam paper topics and long questions.

How to get a H1 in Leaving Cert Engineering

By Gráinne Enright - 13 minute read

By Gráinne Enright - 13 minute readGráinne is an electronic engineer and teacher who has corrected state exams, written mock papers and mentored and patented prize-winning technical projects in the Young Scientist competition. In this guide, she gives her advice on getting a H1 in Leaving Certificate Engineering.

Jump to:

Introduction

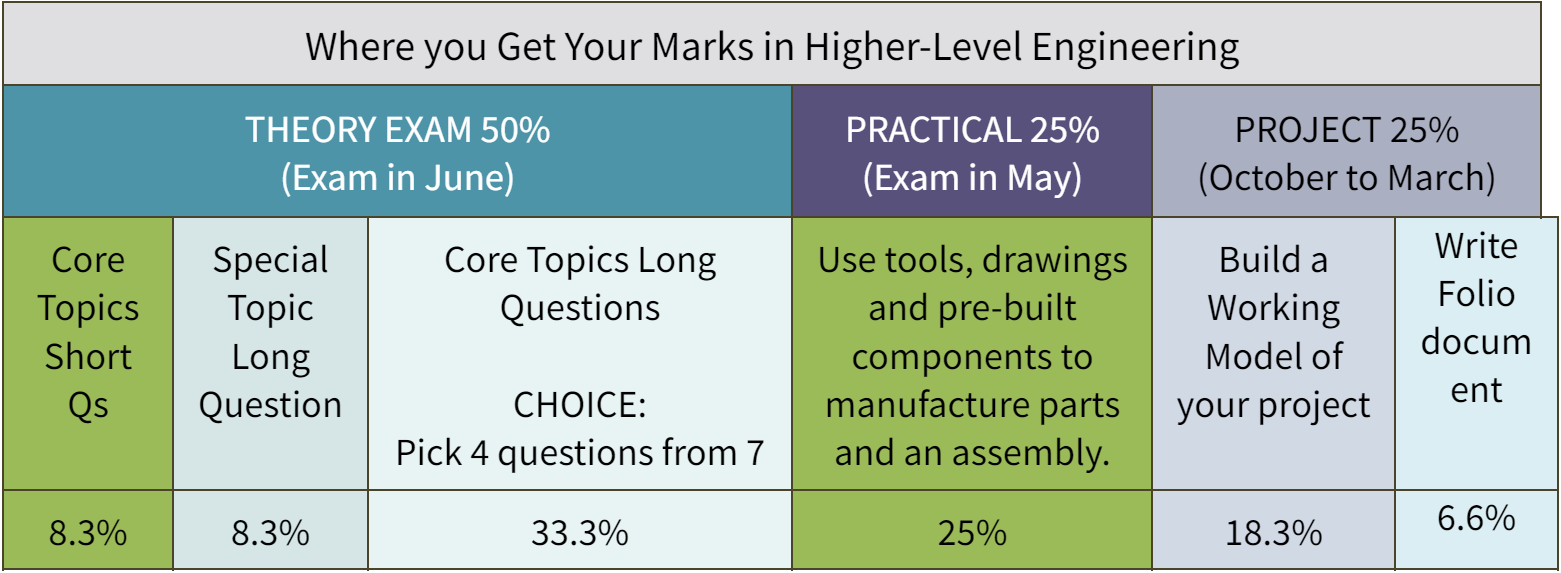

Breakdown of the marks

You can get great results if you spend your time on where the marks are going. Let's have a closer look:

Theory exam

50% of all your marks are won or lost in the theory exam. Therefore, you should spend 50% of your time on theory and practicing exam questions. The biggest block of marks (41.6%) is going for the core topics in the theory exam so you really need to do well here in order to get a good result.

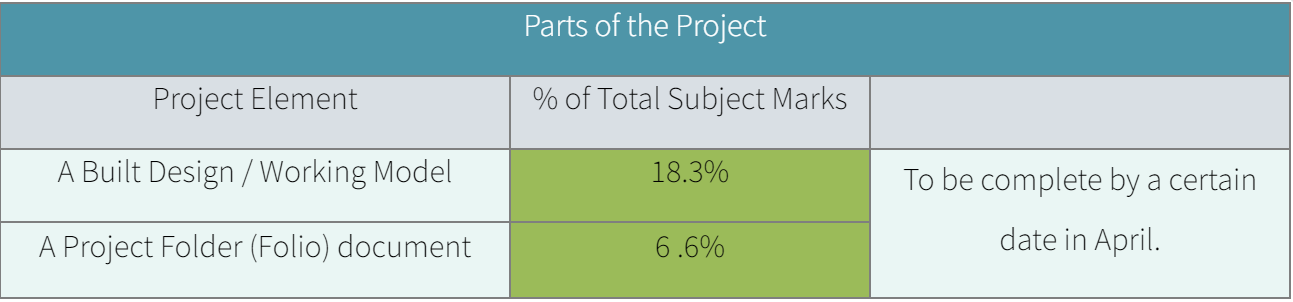

Your built project

18% of your marks are going for your built project. You need to make sure you do a good job but be careful not to spend too much time on it.

The project folder

The project folder (folio) document is worth an extra 6.6% (almost as much as a whole long exam question) so it’s worth doing a good job here too.

Practical exam

You can get up to 25% by doing a good practical exam so it’s well worth putting effort into getting prepared for it (more on this later).

Have a look at the diagram below (the size of the boxes shows the importance of each area):

The theory exam

The theory exam is really important because it is 50% of your marks. Here are some top tips for revising it:

Do lots and lots of previous higher-level exam questions.

Do practice questions on the 'special topic'.

Understand the choices you have in the exam paper.

Read through the full exam paper and time yourself for each question.

Take your teacher’s advice on what choices to focus on and what ones to avoid. This depends on your strengths and what you’ve studied in class.

Get to know the topics and the choices in the exam

The diagram below shows you how the higher-level exam is structured and what kind of choices you have. As there is a lot of choice, you can use this to your advantage. You must do the short questions and the special topic long question but you only have to answer four out of the seven core topic long questions.

With some long questions, there is a choice within the question as well, for example, there may be two (c) sub-questions (on completely different topics) and you can choose which (c) sub-question to do. You can see these choices on the diagram below:

Section A: short questions

There are 13 short questions and you have to answer 10 of them. The short questions cover all the core topics of the course/book and as the questions and answers shouldn't be too long or complicated, the best way to revise for this section is to just do lots of them. You’ll soon begin to see the kinds of questions that come up and you’ll start to get good at them. The short questions can include a wide variety of questions on non-metalwork-related areas such as:

Inventors

Computers

Electrical and electronic devices

Mechanisms

Forces

Pneumatics

Robots

Materials

Corrosion

Plastics

Manufacturing

Mining

Safety

As the short question section is usually very straightforward, it is worth making sure you have practiced short questions. While revising, if you come across a question you can't answer, you can look it up on Studyclix (marking scheme), check your textbook or ask your teacher. That way, you’ll know it for next time.

Section B: special topic question

The special topic (also called the ‘prescribed topic’) is one long question in your exam which is usually split into 4 or 5 parts. It is a different topic and a different document every year that your teacher will cover in class. The 'special topic document' usually has summary points at the end (these are really great for revising) and there is often further information available too, such as slides and videos.

As it is a different topic every year, there won’t be any previous exam questions to practice on but your teacher will set you questions on it. However, there will be a question in the mock paper on it so you’ll get an idea where you are by doing those.

Section B: long questions

The best way to prepare for this section is to do lots of previous higher-level exam questions. Exam paper booklets and Studyclix are perfect aids for this.

First, practice all seven exam-long questions from a number of previous exam papers to see which you are strongest at and where you need to study more. If you haven’t covered certain topics in class, you are unlikely to want to choose those topics in the exam. You can choose not to study certain topics for the exam-long questions because in previous years there has always been a choice of topics in those questions. However, you are taking a risk if you do not study all areas for the exam. Take your teacher’s advice on this.

Most of the marks in your exam come from the core topics section so that’s where you need to spend most of your time revising.

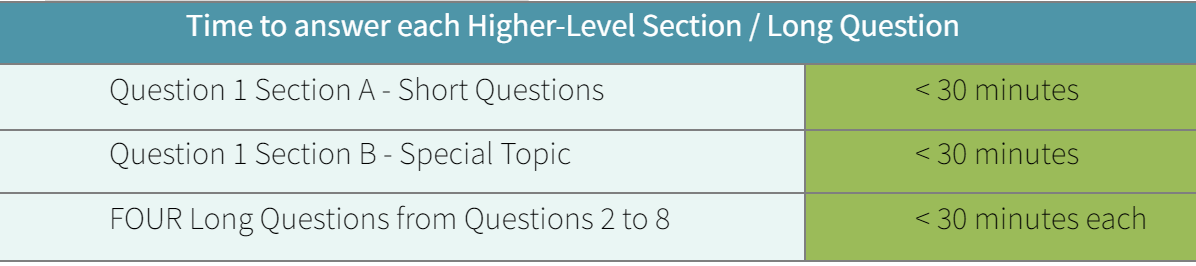

Timing

First, read through the entire paper so that your brain knows what’s coming up. This might also help you get an idea about which four long questions you might like to do.

Allow yourself slightly under 30 minutes to answer each long question or section as this will leave you a few minutes at the end to go over your work. Here's a quick breakdown of timing in the exam:

I recommend starting with the short questions to ease yourself into the exam. When it comes to the special topic question, be careful about any 'or' words in the instructions and only do the parts you need to.

Then, look at the remaining long questions again (questions 2-8) and decide and mark which four questions you are going to do. If you're running over time on a question/section, move on to the next one as you may be able to come back to it later.

Finally, use all the time you have and do not leave early. If you have time at the end, go back to any skipped questions and check previous answers. If you still have time left, do another long question as you will be marked on your best answers.

The practical exam

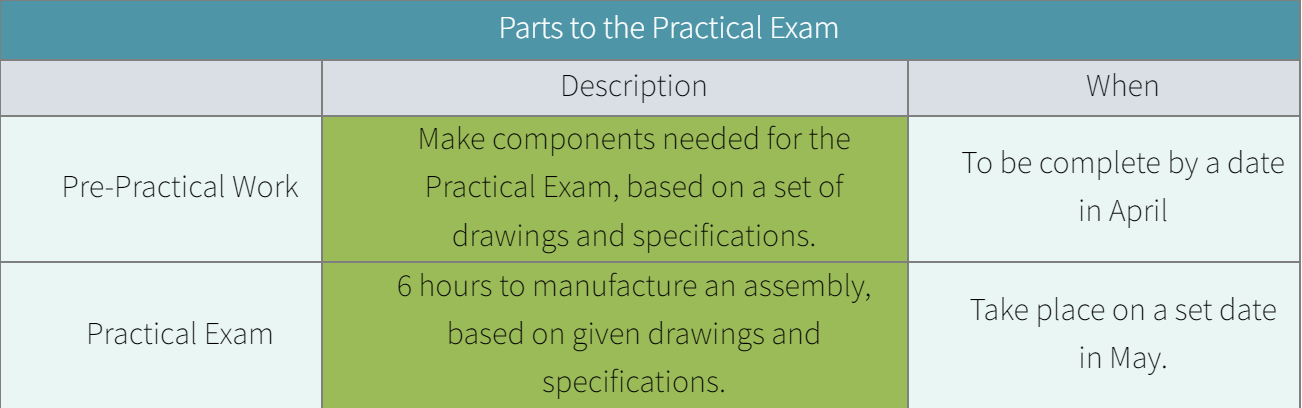

The practical exam is worth 25% and is made up of two parts:

Pre-practical work

You can manufacture some components in class so there is less exam pressure. However, it is important that you start these early and make sure they are ready well in advance of the required date. Try not to leave it until the last week as you may make mistakes and have to start over from scratch.

This work needs to be completed before a set date in April and the better you manufacture these components, the better and easier the practical exam will go for you. Make sure to:

Double-check all of your drawings and measurements.

Mark out and then check the marking out before you use any tools on it and again after using the tools.

Get your finishes smooth.

Not use machines and tools other than those you are allowed to.

Prep for the practical exam

Before

You need to start preparing well before May. Look at previous years’ higher-level practical exams and make sure you understand the drawings and instructions. Try making the objects from previous years’ higher-level practical exams in class. Finally, make sure you have all the parts, tools and equipment needed for the practical according to the list provided.

During

This takes place for six hours in May. During the exam, it is important to read the drawings and instructions very carefully. Decide what order to make the parts in, taking into account the materials and tools needed and how they need to fit together in a final assembly. Make a plan for your time, including:

The time to mark out and make each component.

The time to create the final assembly (and any sub-assemblies).

The time for final polishing and finishing.

Measure twice and check your marking out before and after using tools.

A good exercise is to think about how the examiners are going to mark your practical exam, remember that:

Marks will be going for each part (so make sure you make all parts).

Marks will be going for the main features on each part, e.g. holes, slots, profiles, lathe work and bench work.

Marks are going for the final assembly (and whether it functions) and for the overall quality of the finish and polish.

If there were four main parts, 20% of the marks would go for each part and the final 20% would go for the final assembly and the overall finish. This can vary, however.

The project

The practical project is worth 25%. You receive a 'project brief' (short document) in October and you need to deliver two things, usually in early April.

The higher-level project is different from the ordinary-level project in that the focus is not just on manufacturing, you also need to do and show your own research and design ideas, production planning and drawings. You then need to write up evidence of these in your project folder.

Plan it out

A key to doing well in the project is to plan it out at the start, this is because:

It will take you longer to do things than you think.

There are more stages to the project and more sections in the project folder (folio) than you think.

You have to have a plan in your project folder anyway.

It’s your project, the teacher is not going to do it for you.

Planning and running your project

Start early in the year and plan to finish well before the deadline. I recommend using a template for your project folder; keep a rough version and fill it in as you go along every week/month. Type it up neatly later and make sure you have good drawings to transfer into the final version.

Check in with your teacher often and ask for advice on:

Your plan and what stage/activity you should be doing now.

Your design ideas and how you’re going to manufacture it (your choice of materials, components and processes, etc.).

Your project folder as you are compiling it.

Your project model as you are building it.

Keep your design as simple as possible (while still meeting the brief) as you need to be able to make it easily within the time and with the resources you have available. You also need time to write up a good project folder.

Here’s one idea of how a project might be planned out:

| October/November |

|

| December/January |

|

| February |

|

| March |

|

Checklists

Before you complete or build your design, check your design against the type of checklist that the examiner will be using below and then check it again while building it.

What examiners will be looking for in your built project (model):

Is it/does it do what was asked for in the project brief?

Did it observe the constraints specified in the project brief (e.g. not using bought-in parts, sizes, voltages or any other restrictions)?

Does it show creativity in the design process?

Was a prototype mocked-up?

Does it use a range of appropriate materials in the design?

Does the design use appropriate component parts?

Does it show that different processes were used to manufacture and assemble it?

Did it use CNC processes in the manufacturing?

Does it show a good level of skill in the manufacture and assembly?

Does it show a high quality of manufacture/assembly and a high-quality finish?

Does it show that health and safety were taken in to account?

Does it work?

As you are doing your project folder, check it against the type of checklist that the examiner will be using below.

What examiners will be looking for in your higher-level project folder:

Is it presented well and easy to read? Are the sections in a logical order?

Does it have an ‘analysis’ section (including a description of your understanding of the project brief and details about what else might be required and important in the design)?

Does it have an ‘investigation of solutions’ section(s)? Does it describe the research you carried out?

Does it include clear reasons as to why you decided on your final design?

Does it show that you considered safety in your design?

Does it include a plan (schedule) for the project, showing the time planned for each stage (e.g. investigation, design, building, testing, improvements and final folio)?

Does it include a detailed list of components and manufacturing and assembly drawings for your design?

Does it include a description of how to make, finish and assemble the parts?

Does the project folder include CAD-produced drawings?

Does the project folder describe how you tested the product against the project brief/requirements?

Does the project folder describe what didn’t work initially and what had to be changed?

Does it evaluate the built product (what worked well, what could have been different, etc.)?

Does it include an evaluation of the overall project (what stages had enough time and worked well, what you would do differently next time, etc.)?

Top tip summary

Tops Tips

Theory exam

Know where you get your marks in Leaving Cert Engineering and plan and prepare accordingly. Concentrate on your theory exam as 50% is going for this. Do lots of previous higher-level exam questions and ensure you understand your options in the exam paper. Time yourself for each section and each long question in the exam.

Practical exam

Build all the components needed for the exam well before the deadline. Practice by building from previous years’ practical exams.

Project

Start your project early, plan it out and finish well on time. Use a project folder (folio) template and complete all the sections. Check your design, your built item and your project folder against the checklists provided above.